We have received a number of requests for guest authorships of the newsletter, and have decided that we will accept some of these, given that the content fits with our philosophy and the content is balanced and well-researched. The first of this kind is the following article, which is written by Dr KT Tan, Chief Technical Officer of Viridian Solar.

Quoting the famous, or infamous, phrase coined by Donald Rumsfeld:

…there are also unknown unknowns - the ones we don't know we don't know.

Although this newsletter is far from Rumsfeld’s field of warfare, there is a palpable sense of tension in the PV industry about the risk of a PV fire. On one hand, there is a tendency to sidestep the issue either through denial or ignorance; and on the other hand, there are quarters who exaggerate the situation amounting to scare mongering tactics.

One thing is certain - there are unknown unknowns in the risk of PV fire, we simply want to understand the risk subjectively and scientifically, full stop. In this article, the focus is on solar PV installations on flat roofs, and what we can do about them.

What do we know and what do we don’t know?

It is a fact that there have been fire incidents on flat roofs with solar PV arrays – this is evidenced by the various media coverage. Some examples, like the ones in Bristol, Peterborough and Heerenveen, were presented in an earlier Burning Matters Newsletter, and other cases like the ones in Secaucus (NJ, USA!), Plainview (NJ, USA!) and Piscataway (NJ, USA!) have recently been shared by Grunde Jomaas on LinkedIn.

It is also a fact that under certain circumstances, such as the right air gap and voltage potential difference, the DC electricity can generate arcing.

However, to the best of my knowledge, no one has witnessed and recorded the beginning of a real PV fire, and categorically linked these two facts together. This is a bit like the Big Bang theory, there are some sound theoretical explanations to hypothesise the event, but no one has ever witnessed it (naturally!).

Through painstaking forensic fire investigation, sometimes one may find the tell-tale signs of DC arc faults causing the fire. Again, this is like proving the Big Bang theory by collecting the aftermath evidence – say the cosmic microwave background, the measured abundances of elements and the observed expansion of space.

What if we can recreate the arc fault and observe the beginning of the PV fire? What if we can simulate a real-world installation and learn from the sequence of events?

We know from previous research, for example the excellent MSc and PhD research by Jens Steemann Kristensen - see the papers in his Google Scholar profile - that fire can spread underneath the solar PV on flat roof due to the flame deflection and its characteristic airflow. However, this and other research was mainly based on burning brand sitting on the roofing membrane. What if the source of fire was an arc fault suspended in the air that is closer to reality?

This was the challenge that we set for ourselves and the fire experts from FRISSBE.

What are the industry regulations to safeguard the PV installations?

Unlike the Big Bang theory, we do have some controls over what and how to install solar PV on flat roofs. It is important to understand the existing safeguard in place before trying to recreate our own “Big Bang” event.

Mind you, like the elusive Theory of Everything, it is also important to recognise that there are no internally harmonised fire standards for PV on flat roofs currently. So, the review below mainly focuses on European or UK applications.

All solar PV modules have to fulfil certain qualification standards before they can be placed in the market. In Europe, this includes EN 61730 which contains an element of fire classification (MST 23) – this section deals with the spread of external fire and subsequently refers to other standards like ENV 1187, EN 13501-5 and ANSI/UL 790.

As for the DC connectors, which are considered a critical component, there is IEC 62852 to ensure that the certified products are fit-for-purpose. Although there is neither fire test nor arcing test in this standard, the assumption is that the certified products should perform flawlessly if installed correctly.

Now, let’s look at the materials where the solar panels will be placed on the flat roof. Like most building materials, they have to comply with the requirements of reaction to fire and fire resistance according to EN 13501 with the corresponding Euroclass rating, which has been a well-established system since the turn of the century.

All the above relates to product standards. What about the installation process? Step forward IEC 62548, which primarily forms the backbone for most PV sections in national electrical wiring requirements, e.g. Section 712 of BS 7671 in the UK - this will be cascading down to IET and MCS guidelines. In short, a risk assessment should be carried out to minimise the fire risks, e.g. keep DC connectors out of water and follow manufacturer’s instructions for fire safety. In Europe, the FRISSE (ZAG) published a unique Fire Safety Guideline for Building Applied Photovoltaic Systems on Flat Roofs based on many years of research, recommending the best practice for flat roof constructions. It was presented in a webinar last week, and the recording will be available soon, the people behind it promised. In addition, the motivation and main messages in it were presented in the Fire Science Show Podcast.

With all the above controls in place, what can go wrong? Are we in a better place or do we simply have a false sense of security?

Most fire standards are based on the spread of external fire – what happens if the source of fire is an arc fault underneath the array?

Are the existing fire standards adequate to address the relatively new technologies like solar PV? This is a very serious question that deserves another article altogether. Let’s focus on understanding the fire risk of solar PV on flat roofs for now.

How to design the experiment?

Luckily for us, in order to understand this, we don’t need to have a budget of the Large Hadron Collider to design the experiment. However, we do need to have the best minds in the field to help us to navigate through all the unknowns.

Grunde Jomaas and his brilliant FRISSBE team - we worked particularly close with Nik Rus and Kirils Simakovs - helped us to fill that void and bridge the gap (literally as part of the arc generating process!).

In the absence of any standard for testing, we also consulted other fire experts like Folkert van der Ploeg (Brandweer Twente), Tracy Bradford (University of Central Lancashire) and Ali Nadjai (University of Ulster), who all provided valuable feedback for the project.

After some trials and errors, the team established a way to simulate and sustain arc faults – they were generated by creating a deliberate gap between two conductors of regular DC connectors. The source of the power was based on DC electricity representative of a solar PV installation. An arcing duration of five minutes was chosen for each experiment.

To reflect a realistic installation, the DC connectors were suspended above the roofing membrane by 50 mm, as per the common practice.

Two types of roofing membranes were considered:

Bitumen that consisted of 5 mm top layer (EN 13501-5 Broof(t1)) and 4 mm base layer (EN 13501-1 Class E).

EPDM with 1.14 mm top and base layers (EN 13501-5 Broof(t1-t2))

The membranes were sandwiched by 40 mm mineral wool (EuroClass A1), and placed on top of 150 mm EPS (EN 13501-1 Class E), i.e., from bottom to top - EPS - membrane - mineral wool - membrane - PV panels. The buildups represented retrofit scenarios in flat roof construction, but can also be used for newbuilds, if that is deemed a meaningful solution.

In terms of solar PV arrays, we opted for two different configurations to explore the different characteristics in airflow and flame deflection:

South facing array (single panel)

East-west facing array (four panels)

With the above combinations, the experiment covered four scenarios that allowed us to investigate the consequences of an arc fault in commonly installed configurations.

How did the experiments go?

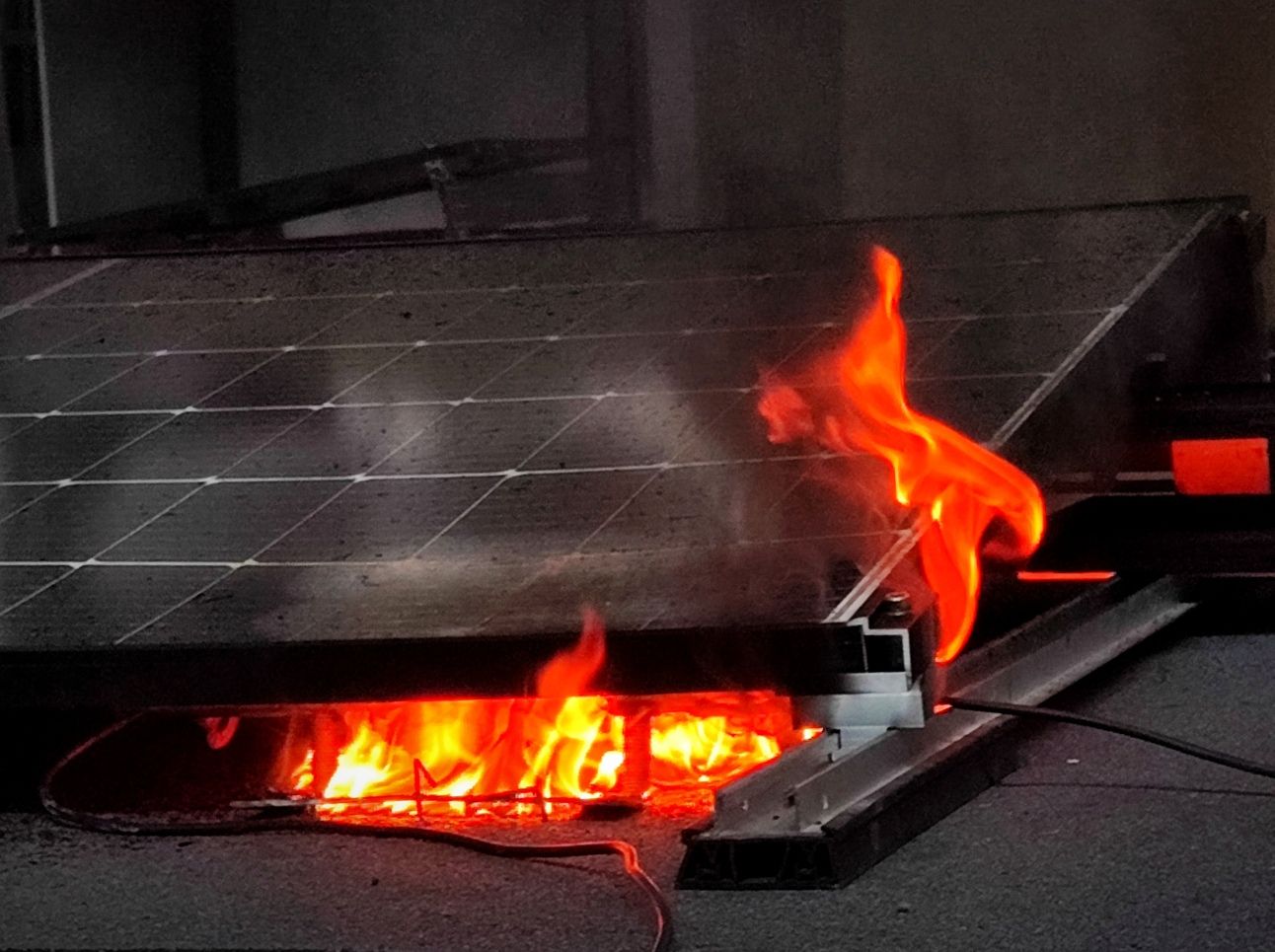

In a nutshell, all the scenarios went up in flames and the membranes below the PV panels, which collapsed, were more or less completely consumed in less than half an hour! Note that the mineral wool prevented ignition of the EPS.

The ignition of the membrane occurred after about 3 to 5 minutes due to the arc and falling debris touching the top surface. At this point, the burning membrane coupled with the heat produced by the arc and the heat reradiation from the panel facilitated the fire spread that eventually covered the entire PV array.

Figure 1: Arc generation - note the very bright light

Figure 2: Flaming ignition - note the different color as compared to the arcing

Figures 3: The fire spread to the entire PV array

The experiment showed that the fire can be started with an arc fault in a realistic position above the membrane, and it can spread through the entire area of the array rapidly on EN compliant flat roof materials.

What can we do about it?

Clearly, besides trying to understand how real the fire risk on flat roofs is, the next question must be what we can do about it.

Obviously, the best approach is to prevent the arc faults altogether in the first place. This can be done through proper installation training, regular maintenance and electrical devices like AFCI. However, all these involve some elements of human errors and certain degree of uncertainties, as presented in a large survey by Clean Energy Associates, who found safety issues in 97 percent of the 600 commercial rooftops studied . ”Persuade thyself that imperfection and inconvenience are the natural lot of mortals, and there will be no room for discontent, neither for despair” - Tokugawa Leyasu.

Viridian Solar invented and launched a simple product called ArcBox to contain the arc and prevent the fire from spreading. The experiment was the perfect test bed to gauge the effectiveness of ArcBox in these scenarios.

The aforementioned experiments were repeated with ArcBox deployed at the DC connectors. Keeping all the test conditions the same, i.e. duration, setup and location, the outcome was reassuring, but boring in the sense that nothing happened!

Figure 4: Arc generation inside the ArcBox

Figure 5: The fire was contained inside the ArcBox

In all scenarios, the ArcBox was able to prevent ignition by an arc fault and thus prevent flame spread around the PV array.

What did we learn from these experiments?

So, what are the learning points? I think they can be summarised with the following:

The risk of fire is real! An arc fault at a realistic position from solar PV on flat roof can cause the spread of fire, even on compliant roofing membranes.

For the same specific condition, the spread of fire also occurred at different array configurations.

With the introduction of ArcBox, it can effectively prevent ignition by an arc fault in all cases. Without the use of an ArcBox, the same arcing results in significant flaming and finally spread across the membrane below the entire area covered by PV panels.

Although these scenarios represented the majority of commonly installed arrays, future work should be extended to look into the effects of arc fault position, duration, pitch angle and different material combinations.

Without sounding like a scaremonger, the risk of PV fire should be put in context, as studies have shown that fires are expected to happen at a frequency of about 29 fires per GW installed. Studies and figures from fire departments estimate the probability of a fire for rooftop PV system to be less than 0.01%. That might sound low, but with millions of installations as the solar PV installations are becoming a viable source of renewable energy, a small percent can result in a significant number of incidents.

Still, I want to emphasize that the solar PV is a promising, safe renewable technology that will play a big role in the energy transition. We should be vigilant and manage the fire risk proactively, so that it would not spread like wildfire!

At least for now, we have managed to capture a glimpse of the “Big Bang” event and understood how they led to the eventual spread of fire in a control environment – these cold, hard facts ‘ain’t pretty’ but we are safe in the knowledge that there are products like ArcBox to give you the peace of mind. There may be other complementary approaches out there, but we need to act now!

Written by

Dr KT Tan

Chief Technical Officer of Viridian Solar

Chair of the BSI GEL/82 solar PV committee, Chair of the MCS PV working group and Convenor of the IEC TC82 WG8 PV Cell Technologies

Viridian Solar is one of the financial supporters of the Burning Matters Newsletter.

We would love to hear your thoughts! Reach out through the Burning Matters feedback form.

Find more details about ArcBox and Viridian Solar here: